In this how-to install a sub-panel installation I will guide you through the complete installation of a subpanel step by step.

The first question is why are you installing a subpanel. There are either one or two reasons to do this. One because you need more room in your existing panel and in that case if your existing panel is old this would be a great time to just upgrade your current service. Newer 200 amp main panels hold a lot more circuits/breakers.

Two, because you need to bring more power somewhere else like a garage you just built or addition or even in some cases a finished basement. Either way, you want to install a subpanel. Ok. So let’s get going.

First: Where do you plan on placing the new sub-panel? If it’s right next to your main panel that’s one thing, but further away like in that new garage you just built 100 feet away you will certainly want to figure in voltage drop. I can’t get too much into that because every setup would be different.

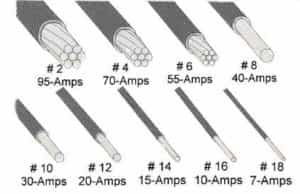

Second: How many amps are you needing for the new sub-panel. So let’s say you need 50 amps. Well, it’s not brain surgery, 50 amp sub panel, 50 amp wire, 50 amp breaker in the existing main panel. See wasn’t that easy.

Neutral Bonding Jumper:

This is very very important. This is also known as a bonding screw. It may even be green. This screw is used to bond the neutral coming in the main panel to the case “panel” itself. however, in a sub panel, the neutral bus bar must be totally isolated from the ground. The very first thing the electrical inspector is going to look for is if the sub-panel is bonded or not.

Now as far as wiring the panel. You would wire it just like any other panel. Hot leads to the breakers, grounds to the ground bus bar, and neutrals to the neutral bus bar.

But Why Do You Need To Remove The Green Screw?

Because the neutral only gets bonded at 1st means of disconnect so any unbalanced load only has one true path to the ground and that’s at the power source.

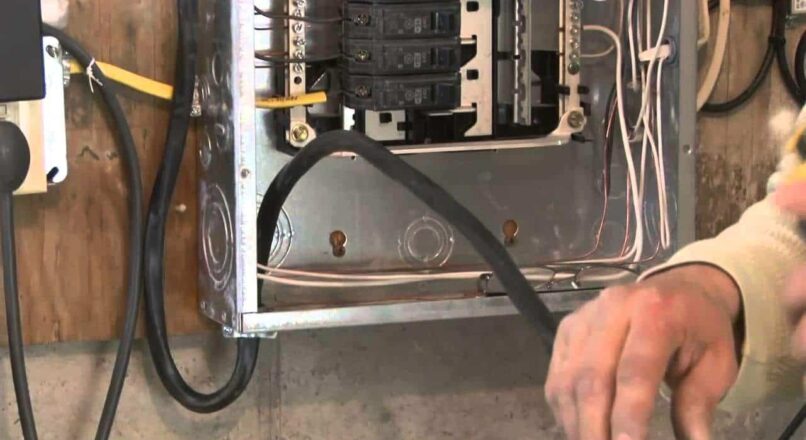

You would install a 220-volt two-pole breaker in the main existing panel. Whatever the amperage is that you’re using. That breaker gets installed in the main panel of course. This is now the main breaker to your sub-panel. By turning this breaker on or off will control the entire subpanel.

Always remember safety first. Turn the main power off before removing panel covers or touching any wires.

You will need a 4 wire, wire between each panel. No matter how the panel is, this part will always stay the same. You will have two hots, one neutral and one ground. Two hots will go from the new breaker you just installed in the main panel to the sub-panel. A neutral will go from the neutral bus bar in the main panel to the NON bonded bus bar in the sub-panel and ground from the ground bus bar in the main panel to the bus bar in the new sub-panel.

Comments ( 74 )

So then the neutral and ground wires both connect in the non-bonded singe bar in the picture above, correct?

Yes

Dominick,

Great Video.

I’m trying to decide if it would be better to install a sub panel on the side of the house to service the backyard. It would be nice to have a convenient place to run wire from but right now I don’t see a need for more than 2 circuits, so I could probably run it from my main panel in some conduit. What would be the max distance you would run a 12-2, since this will be the determining factor as to whether I install the panel.

Your thoughts?

On the very bottom of this page look for the electrical wire calculator. That should help you out. And yes I would not run a sub panel just for that.

Hi Dom, do I need to connect a ground wire from main panel, to the sub panel “Garage”?

I am putting in a ground rod for the sub panel.

Seems like if I do add the ground wire from the main panel, there will be no isolation of the Natural and Ground in the sub panel. Can you explain this for me.

Thanks for all your time, you are an inspiration to your trade.

Bill

Yes you should have the ground from panel to panel. But what kind of wire do you have installed?

New construction, 200 amp homline. I’m feeding a 100 amp sub panel. Right wire, no bond screw in the sub panel, separate ground bus bonded and grounded with new ground rod. In coming ground from 200 amp is connected to this bonded ground bus bar. No loads on sub panel. When I turn on the 100 amp double pull breaker to energize, it trips immediately.

Bond screw is in 200 amp panel and working great. With the bond screw in, is there a difference in what bus bar I use for ground and neutral?

What about the neutral in the sub-panel?

My old 24″ wall ovens are dying. One is dead and the other is giving error messages. So, I’m forced to upgrade right away to a new 27″ double oven. I say “forced”, because this kitchen needs a total renovation which is maybe two years off. I can’t just swap the new for the old unit and use the old cable because I discovered recently that someone in a earlier rehab installed it improperly–they hard wired the ovens directly into the back of an old screw fuse panel box mounted in the rear of one of the base cabinets at the other end of our galley kitchen layout.

As long as I need to replace the ovens now, I thought I’d install it safely into a new kitchen sub-panel mounted in the cellar. The sub-panel would be used for more circuits when I do the total kitchen rehab.

The cabinet has enough width to fit the larger unit… and I’m great at carpentry–no problem there…. and although I’ve done all my own electric for about 40 years, I’ve never installed a sub-panel before so I could use some advice:

Subpanel suggestions:

Subpanel must be big enough for at least 6-8 20 amp breakers and the 40 amp/220 required (I checked the specs of the oven I’m getting) for the ovens and am I right in thinking the panel should be for 100 amp? (I have 200 amp service in the main panel). Cable size for the oven circuit… #8/3 w ground? What cable size and type for the subpanel… wait… there are two scenarios for subpanel placement I’d like opinions on….

Layout of the house:

Triple brick house with stone foundation cellar under the main house… Kitchen ell has joists under the floor but only 4-6″ space between the bottom of the joists and the dirt below. There is a small break at the top of the stone foundation wall leading to the kitchen ell (for plumbing pipes) that I can use for the cable runs. This spot is about 18 – 20 feet from the oven location and about 45 feet from the main panel.

Subpanel placement Options:

1) to put the panel next to my main service panel (very short feed cable between them) and do ALL cable runs from there (about 60-65 feet away from the oven location)… that’s a lot of cable (#12 romex for perhaps 6 circuits eventually). And what cable type and size would I need to feed 100 amps from the main to the subpanel in this scenario (a very short run)?

2) or… mount the subpanel against the back cellar wall which can get me within 20′ from the oven location. The larger feed cable run is longer at about 40-45 feet (any difference in cable size/type for this length of run?), and all the future circuit runs would also be shorter.

3) which method is better/worse considering electrical resistance and cable costs (future circuits too)?

BTW… the real hassle in this job is going to be snaking the cable under the kitchen floor to the existing cabinet that I’m going to expand for the 27″ new unit. The cabinet has a 5″ drawer under the wall oven cavity… there is a back and bottom to the cabinet (looks to be 1980s vintage)… I’ve got full 1″ thick floorboards and Lord knows how many layers of plywood and linoleum/asphalt tile/vinyl sheet goods I’ve got to get through… and somehow I’ve got to snatch a #8 Romex cable. The cellar under the main house is no problem… but there’s that 20 feet or so I’ve got to snake cable under a 5 or 6 inch clearance under the kitchen joists to get from the cellar to the oven location. I’ve got fiberglass fish poles to snake cable, but making the turn uphill and getting inside that cabinet is going to be a nightmare. Another idea is to use conduit and pull THHN wires through to make the connection (what size THHN would I need?). I haven’t done conduit bending and pulling cable in many years and didn’t like doing it back then.

I was thinking of cutting out the bottom of the drawer and the floor under the cabinet and then bringing the cable up into the rear of the oven compartment. Thoughts?

As for the rest of the kitchen circuits… I’ll leave everything until the full remodeling. The cables are fine–all Romex, grounded, GFCIs near the sink, etc…. the fuse box is fine too– I’ve blown maybe 2 fuses in the 17 years in this house. (I make certain my wife doesn’t use two appliances at the same time). It’s just that darned cable to the oven I’ve got to remove and run into a new sub-panel.

Thoughts on my approach to this? I especially need advice (and proper jargon) on the subpanel part of the job? Thanks!

Can spa sub Panel be used for a regular sub panel , I think it can be but want to be certain. It looks like both buss bars are grounded. I understand

Both needs to be separated and isolated. But from the looks of this panel

It seems that way

A spa sub? I would really have to see what you have to make that call.

In my comment below I should have said feeds leaving the top of the current panel sorry.

Hi, yes it is a mobile home. My main service is 200amp. The panel I am trying to add is 100 amp. The only reason I am trying to add the 100 amp sub panel is because they crammed so many wires into shared breakers (including some 220v 20a/40a breakers) and there is absolutely no room to even add one more 220v breaker if needed.

We have about 4 110v 15a feeds coming into the top of the current panel. The main feed and other feeds are coming into that panel from the bottom. I figured that if I add the sub panel above the old panel I can move the 4 110v 15a breakers to the new sub panel above. I have just never seen a sub panel mounted directly above a main panel and not sure if you think anything sounds wrong about doing this.

Dominick Amorosso January 10, 2016

Hi, I assume you’re talking about a mobile home!. In that case, the first question would do you have enough on the main service for what you’re trying to do?

Tom January 9, 2016

Hi Dominick,

Firstly, Thank you for your contribution to this world.

Do you see any problem with installing an in wall sub panel above a currently installed in wall panel inside a manufactured home? The currently installed indoor panel feeds off of an outdoor main panel if that matters.

I do understand that if I installed a panel above the existing indoor panel that I would have to move the wires coming into the current panel from the top to the new panel i install above it. I just haven’t seen it done anywhere else and wanted to know if you see any possible issues with this.

Well if you watch my video you’ll see that the sub-panel is right next to the main panel. A sub for more breakers, or remote to another location. All the same. As far as what you’re doing size wise I can’t say because I’m not there of course.

I installed a sub panel as per your instructions. Now I am installing a 220v 20 amp circuit breaker.

I used 220 3 wire for my saw do I take the ground wire and attach this to the ground bar or neutral bar beings how I do not have both? I was thinking I install it looking at this video to the ground bar.

Thanks

This is all going to depend on if you need a neutral for your saw. Chances are you do not us you could’ve just used a 12/2 wire. So if that’s so just use the two hots and the ground.

Hey Dominick,

Thanks for the very clear and concise video. I’m running a 150 Amp circuit 100 feet to my carriage house. The one question I can’t seem to get a straight answer on is the size of wire. When using the southwire calculator, as well as some others, it says 2/0 for copper and 3/0 for aluminum. But then I’ve seen elsewhere, including in your comments section, peopler running much smaller wire. Like 2 AWG. Specifically a 2-2-2-4. What is the right size wire?

And second question, do I need to run 2 hot, 1 neutral, and a ground? Since my subpanel is grounded through a ground rod are all 4 wires needed? And does the neutral and/ or ground need to be the same size or can they be smaller?

Thanks again for your great videos and help!

2/0 seems about right. But always check this with your electrical inspector. He’s the one you need to make happy. Oh and yes, always two hots and a neutral. If anything the neutral would be bigger, not smaller. The neutral by itself is the return path for both hots. So never smaller. The ground is smaller,